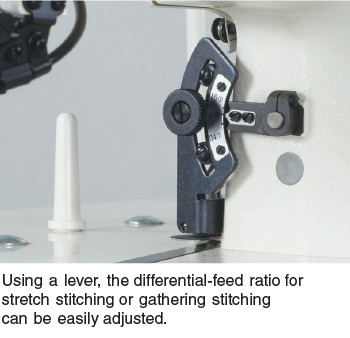

The machine finishes beautiful seams in elastic and light-weight materials. Furthermore, the differential-feed can be adjusted with the simple operation of a lever, thereby enabling the machine to respond to the requirements of many different kinds of sewing.

The machine is provided with mechanisms to enable upgraded sewing

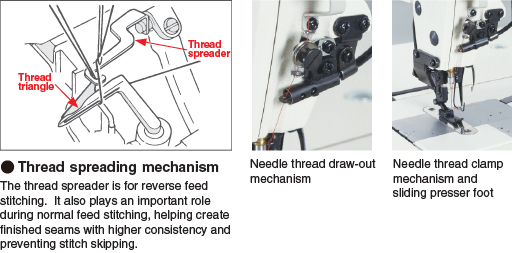

The machine comes with a thread spreading mechanism and an adjustable needle guard to prevent stitch skipping. The thread clamp mechanism, tension release mechanism and needle thread draw-out mechanism enable the machine to leave thread of a uniform length after thread trimming, and prevent slip-off of the needle thread. All of these mechanisms contribute to upgraded sewing.

Safety stitching or reverse feed stitching with a simple lever operation

Safety stitching (condensation stitching) the perfect method of preventing loose stitches, or reverse feed stitching (back-tacking) can be alternated through the simple adjustment of the stopper of the reverse feed lever. Either sewing method can be used.

Beautifully finished seams

Provided with a sliding presser foot and a silicone oil lubricating unit as standard, stitch skipping and puckering are prevented. Furthermore, the silicone oil lubricating unit prevents the needle from overheating, and allows foundation yarn or synthetic thread to be used without breakage during sewing. These features assure beautifully finished seams with consistency for light- to medium-weight materials.

The machine is capable of gathering and partial shirring

A gathering attachment (S060), intermittent gathering attachment (S061) and partial shirring device (PF5) are optionally available to enable the machine to perform consistent gathering and partial shirring.

Replaceable gauges such as the gauge for light-weight materials and the urethane feed dog are prepared in accordance with the applications of the machine.

Change of sewing method with a simple lever operation

The sewing method can be alternated between stretch stitching and shirr stitching with the simple operation of a lever. This lever is also used to adjust the differential-feed ratio.

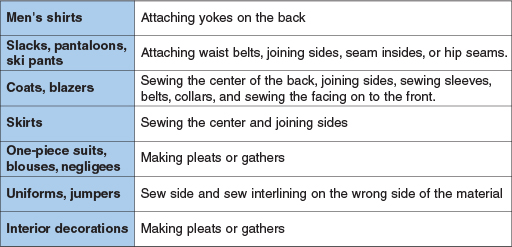

APPLICATION FOR MH-481 SERIES

Specification

| Model name | MH-484 | MH-484-5(4) |

|---|---|---|

| Feed system | Differential-feed | |

| Max. sewing speed | 5,500rpm | |

| Stitch length | Main feed: 1~4mm Differential-feed: 1~5.6mm | |

| Top-feed amount | – | |

| Differential-feed ratio | Max. gathering stitching 1: 3 (standard 1: 1.5) Max. stretch stitching 1: 0.5 | |

| Lift of the presser foot | By hand: 5mm, By knee: 10mm | |

| Needle bar stroke | 30mm | |

| Needle (at the time of delivery) | TV × 7 (#11) #9~#18 | |

| Stitch length adjustment | By dial | |

| Safety stitch | Condensation stitch/reverse stitching (by feed lever) | |

| Looper system | Inclined crank | |

| Looper stroke | 21.5mm | |

| Looper stroke of the front and rear | 2.1~3.3mm | |

| Speed control | – | *(1) |

| Lubrication | Automatic | |

| Lubricating oil | JUKI New Defrix Oil No.1 (equivalent to ISO VG7) | |

| Motor output | 750W | – |

| Power requirement | Single-phase, 3-phase | – |

| Power consumption | Rating 425VA | – |

*(1) From 500rpm to the Max. sewing speed determined by the pulley used (externally adjustable)

SPECIFICATION CONFIRMATION TABLE WITH TYPES OF MACHINES

| Model name | MH-484 | MH-484-5(4) | Remarks | |

|---|---|---|---|---|

| Condensation stitch | Provide | Provide | Use the reverse stitching lever Adjust the stopper | |

| Reverse stitch | Provide | Provide | ||

| Thread clamp device | – | Provide | ||

| Needle thread releasing device | – | Provide | ||

| Needle thread drow-out mechanism | – | Provide | ||

| Thread spreader | Provide | Provide | ||

| Movable needle guard | Provide | Provide | ||

| Sliding presser | Provide | Provide | ||

| Chain-off thread presser | Option | Option | Chain-off thread presser foot for the MH-480 series | |

| Silicon oil lubricating unit | Provide | Provide | Provided as standard (packed together with accessories) | |

Gauge

MH-484

MH-484-5

| Guage | THROAT PLATE | MAIN FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT |

|---|---|---|---|---|

| Figure |  |  |  |  |

| Specification | P/N | P/N | P/N | P/N |

| Medium weight | B1103484F00 | B1613484F00 | B1653484F00 | B1524481CC0 |

| Reverse teeth | – | – | B1653484C00 | – |