The MF-7500 Series is a newly developed coverstitch machine provided with lots of mechanisms for improving the seam quality.

It is provided with many different sewing-related mechanisms which contribute to improved seam quality, such as the new feed mechanism, and differential-feed micro-adjustment mechanism. In addition, the machine is provided as standard with a looper thread twining prevention mechanism for improved maintenance.

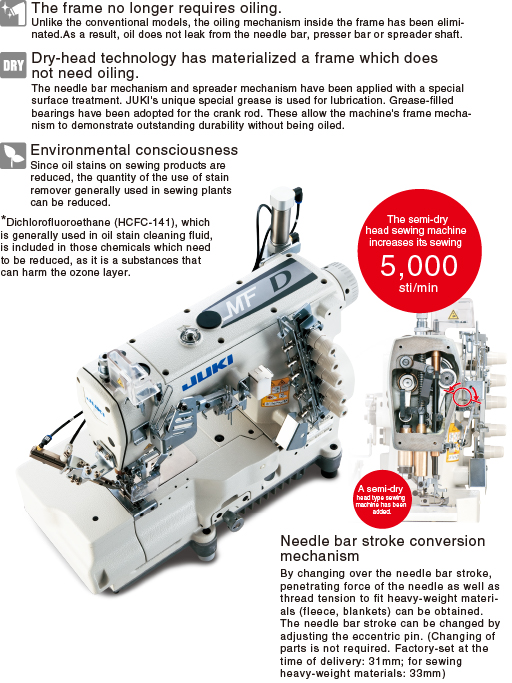

JUKI’s dry-head technology protects sewing products from being stained with oil

With the excellent functions inherited from the MF-7500 Series, the MF-7500D is provided with a dry frame mechanism to eliminate the cause of oil stains. Stain removing work or re-sewing work is substantially reduced by protecting sewing products from being stained with oil, thereby improving the quality of finished products.

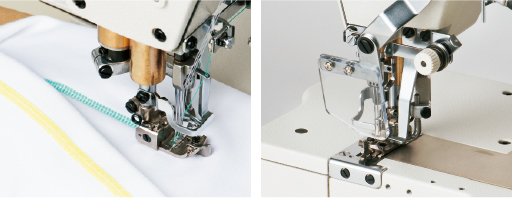

U11 Universal type (basic type)

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for the covering process for sportswear and knitwear. The front cover is trimmed to allow operators to bring their hands closer near the needle entry area, thereby increasing work efficiency in the covering process, etc.

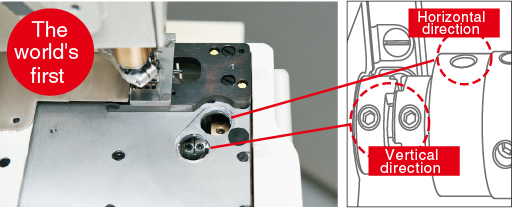

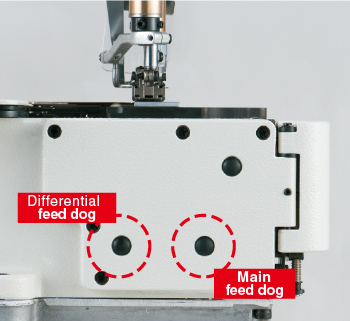

Thanks to the new feed mechanism, many different types of sewing are achieved

The feed locus can be adjusted externally. The feed locus is now adjustable in terms of the vertical direction and horizontal direction, thereby improving responsiveness to sewing materials.

Feed longitudinal position adjustment mechanism

The longitudinal position of the feed is adjustable. As a result, uneven material feed and puckering that are likely to occur when sewing products made of elastic materials such as foundations are reduced. This means that the machine promises improved responsiveness to elastic materials.

Commercially-available gauge components are applicable with no additional work

As a result of the commonality of components, commercially-available components (presser foot, throat plate and needle clamp) are now applicable and easily obtainable.

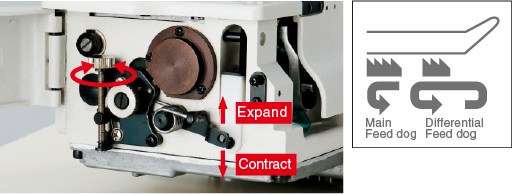

Differential-feed micro-adjustment mechanism

It is possible to finely adjust the differential feed amount to a best-suited value for the material to be used. The differential feed ratio is constant even if the stitch length is changed.

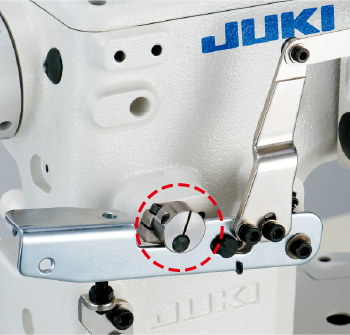

Micro-lifter mechanism

Elastic material or delicate material can be sewn with the presser foot kept slightly raised. This effectively helps reduce the degree of slippage, warpage and damage of the material.

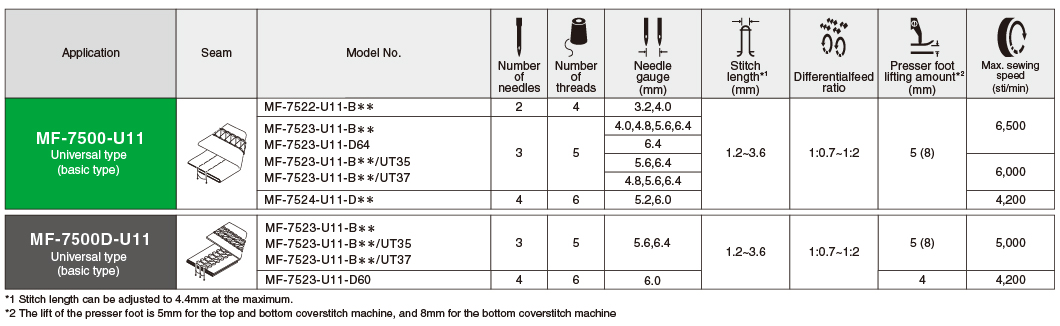

Specification

| Model name | MF-7500 series | MF-7500D series | ||

|---|---|---|---|---|

| Stitch type | 2-needle/3-needle/4-needle top and bottom covering stitch | |||

| Needle | UY128GAS (#10S) #9S~#12S | |||

| Lift of the presser foot | 5mm (with top and bottom covering stitch), 8mm (with bottom covering stitch) | |||

| Stitch pitch adjustment | By dial | |||

| Differential feed adjustment | By micro-adjustment mechanism | |||

| Lubrication | Automatiac | Automatic (frame: no lubrication) | ||

| Lubricating oil | JUKI Machine Oil 18 (equivalent to ISO VG18) | |||

| Feed dog inclination adjustment | Provided as standard | |||

| Micro-lifter | Provided as standard | |||

| Needle bar stroke converting function | Provided as standard: 31mm: at the time of delivery / When sewing a heavy-weight material: 33mm | |||

| Silicon oil tank for needle tip and needle thread | Provided as standard | |||

| Cartridge oil filter | Provided as standard | |||

| Power requirement | Single-phase 100~120V / 200~240V, 3-phase 200~240V (with automatic thread trimmer) | |||

| Power consumption | 500VA (with automatic thread trimmer) | |||

| Weight of the machine head | U11 | 45kg (without device), 53kg (with UT35), 58kg (with UT37) |

|---|

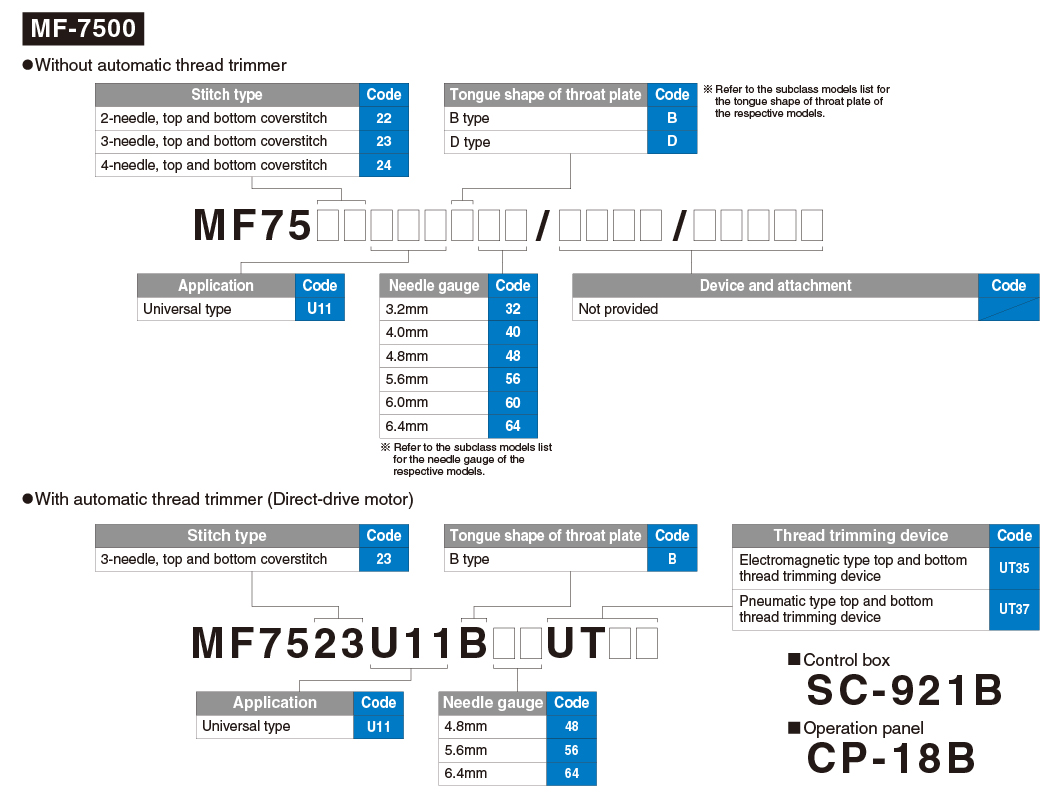

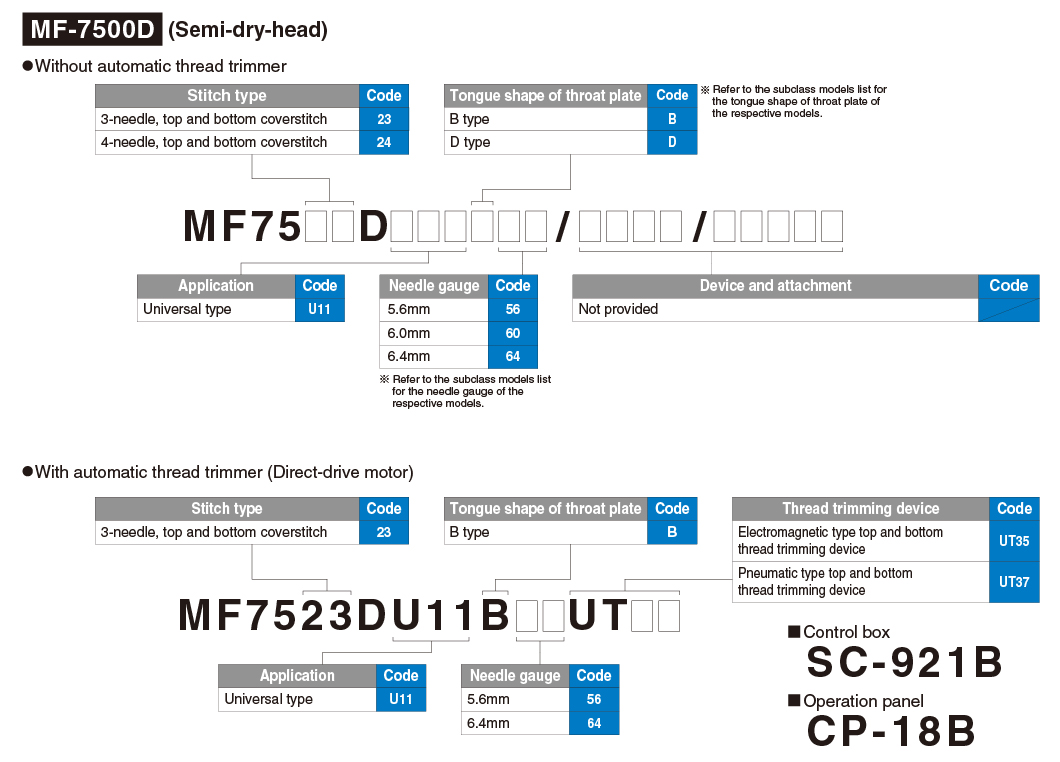

When you place orders

Subclass machine list