JUKI Simple Series sewing machine LK-1900S has been designed to have simplified and narrowed down capabilities that are essentially required to produce JUKI’s established seam quality.

In addition, it supports the operator with the voice guidance system to improve work efficiency.

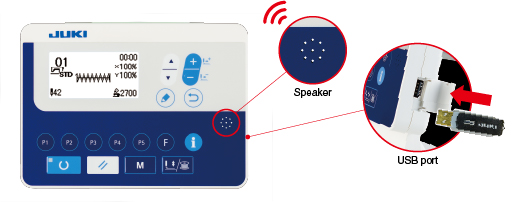

Voice guidance for the operator

This sewing machine is provided as standard with the voice-guidance system with clock function. This voice guidance can be used for the purpose of production support such as giving the operator information about the number of pieces produced, work progress management and the operation rate of sewing machine, though the initial setting is required.

The operation panel is provided as standard with a USB port. This means that the sewing machine data management and software updating can be carried out with ease by means of the USB port.

Higher productivity

This sewing machine shortens the total cycle time with its improved capabilities such as the maximum sewing speed of 3,200 sti/min, quick acceleration at the beginning of sewing and quick deceleration at the end of sewing, increased thread trimming speed and work clamp foot lifting speed.

The sewing machine provides the sewing area of 30mm (length) × 40mm (width)

With its large sewing area, this sewing machine can be fully utilized for sewing various kinds of sewing patterns such as lengthwise bartacking. In addition, the sewing machine has such a large memory capacity to store many different scale ratios, numbers of stitches and numbers of sewing patterns, thereby ensuring improved flexibility.

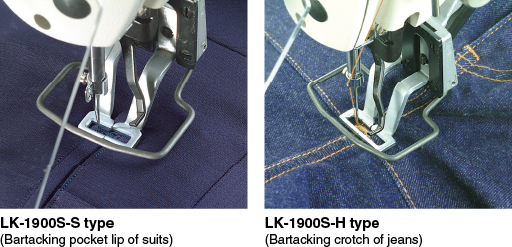

The LK-1900S comes in two different types to allow customers to select the best-suited one

The LK-1900S comes in two different types; i.e., S type (Standard) and H type (for Heavy-weight materials). Customers may select one of these types according to their applications.

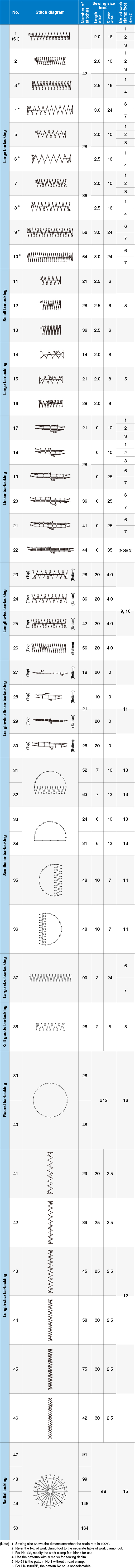

This sewing machine quickly carries out sewing of various kinds of sewing patterns

The sewing machine is provided as standard with 51 sewing patterns with different stitch directions and number of stitches, such as large bartacking, small bartacking, straight line tacking. The operator can select the best-suited sewing pattern according to the given process. (In some cases, the work clamp foot and other parts may be required to be changed.)

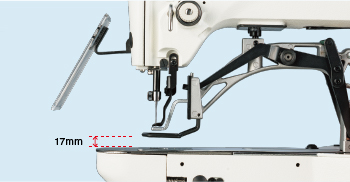

Work clamp foot lifting height

(max. 17mm)

The sewing machine is provided as standard with the stepping-motor type work clamp foot lifting device. The maximum lifting amount of the work clamp foot is 17 mm.

LED light (light quantity in five levels + light-out function)

The LED light that illuminates the needle entry area is provided as standard. The LED light is provided with the six-step changeover switch to control its brightness and light-out.

Excellent responsiveness promises comfortable work

The direct-drive system that directly connects the compact AC servomotor to the main shaft of the sewing machine has been adopted. This system enables quick startup and promises increased stopping accuracy, thereby contributing to improved responsiveness.

Location of the hand pulley allows the operator to check the needle entry with ease

The hand pulley is located at the arm of machine head. This arrangement helps the operator visually check the needle entry with ease.

TABLE OF THE STANDARD PATTERNS

Specification

| Model name | LK-1900S-SS | LK-1900S-HS | ||

|---|---|---|---|---|

| Application | Standard | For heavy-weight materials | ||

| Lubrication | Semi-dry head (Hook: minute-quantity lubrication) | |||

| Max. sewing speed | 3,200sti/min (at the time of delivery: 2,700sti/min)* | |||

| Sewing area | 30mm (L) × 40mm (W) | |||

| Stitch length | 0.1~10mm (0.1mm step) | |||

| Needle bar stroke | 41.2mm | |||

| Lift of the work clamp foot | Standard 13mm (17mm when the reverse-rotation needle-up function) | |||

| Auto-lifter | Provided as standard (stepping motor type) | |||

| Needle thread tension | Spring type dial thread tension controller | |||

| Needle (at the time of delivery) | DP × 5 (#14) | DP × 17 (#21) | ||

| Hook | Standard shuttle hook | |||

| Number of stitches that can be stored in memory | Max. 20,000 stitches | |||

| Number of standard patterns | 51 patterns | |||

| Number of data that can be input | 200 patterns | |||

| Enlarging / Reducing facility | 20~200% (1% step), Pattern enlargement / reduction can be done by increasing / decreasing the stitch length | |||

| Memory medium | Internal-organs memory | |||

| Bobbin thread counter | Provided as standard (up / down method) | |||

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | |||

| Sewing machine motor | Compact AC servomotor (direct-drive system) | |||

| Power supply / Power consumption | Single-phase 200~240V / 250VA | |||

| Weight | Machine head (include motor) 42kg, Control box 5.1kg | |||

*sti/min is the abbreviation for “stitches per minute”

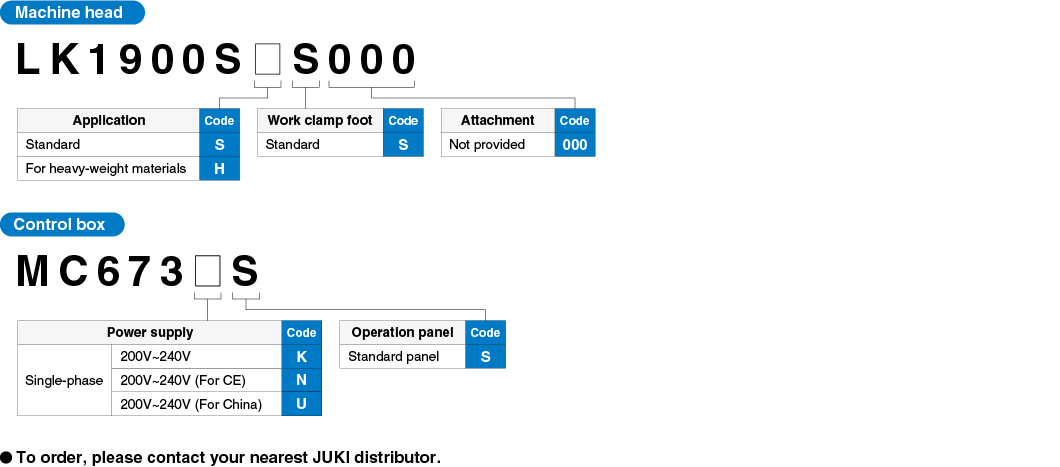

When you place orders

Gauge

LK-1900S-SS

LK-1900S-SH

| Guage: OP | WORK CLAMP FOOT ASM. | WORK CLAMP FOOT_RIGHT | WORK CLAMP FOOT_LEFT |

|---|---|---|---|

| Figure |  | ||

| Remarks | P/N | P/N | P/N |

| – | 13518659 | 13518600 | 13518709 |

| – | 13548557 | 13548508 | 13548607 |

| – | 13548151 | 13548102 | 13548201 |

| – | 13542451 | 13542402 | 13542501 |

| For knitted fabric | 13542964 | 13542915 | 13543012 |

| – | 13571955 | 13571955 | 13571955 |

| Guage: OP | FEED PLATE | FEED PLATE | FEED PLATE BLANK | FEED PLATE BLANK | FEED PLATE BLANK |

|---|---|---|---|---|---|

| Figure |  |  |  |  |  |

| – | P/N | P/N | P/N | P/N | P/N |

| A | 14116107 | 14137707 | 14120109 | 40021855 | – |

| B | 14116206 | – | 14120208 | 40021856 | – |

| C | 14116305 | – | 14120505 | 40021857 | – |

| D | 14116404 | – | 14120307 | – | 40021858 |

| E | 14116503 | – | 14120406 | – | 40021859 |

| F | 14116602 | – | – | – | – |

| G | 14116701 | – | – | – | – |

| H | 14116800 | – | – | – | – |

| I | 14116909 | – | – | – | – |

| – | 13548003 | – | – | – | – |

| – | 13554506 | – | – | – | – |

| D9-14 | 13554803 | – | – | – | 40021873 |

| 12 | – | – | – | 40021876 | |

| 10 | – | – | – | 40021879 | |

| 14 | – | – | – | 40021882 |

| Guage: OP | FEED PLATE BLANK_RIGHT | FEED PLATE BLANK_LEFT |

|---|---|---|

| Figure |  |  |

| Remarks | P/N | P/N |

| Surface | 14121701 | 14121800 |

| – | 14121909 | 14122006 |

| Plating | 40021851 | 40021852 |

| No plating | 40021853 | 40021854 |

| Guage: OP | INNER HOOK PRESSER ASM. | NEEDLE HOLE GUIDE | |

|---|---|---|---|

| Figure |  |  | |

| – | P/N | P/N | Remarks |

| 14103253 | B2426280000 | – | |

| 14103352 | B242628000B | Thick needle | |

| 14103659 | 14109607 | – | |

| B1817210DAD | D2426282C00 | For knitted fabric | |

| – | D2426MMCK00 | – | |

| Guage: OP | FINGER GUIDE | |||

|---|---|---|---|---|

| Figure |  |  |  | |

| – | P/N | Remarks | P/N | P/N |

| 26224204 | – | 14120000 | 14135305 | |

| 13548300 | – | |||

| 13573407 | Vertical bar | |||

| Guage: OP | WORK CLAMP ASM. | WORK CLAMP ASM_RIGHT | WORK CLAMP ASM_LEFT |

|---|---|---|---|

| Figure |  |  |  |

| P/N | 14121263 | 14121255 | 14121354 |

| Guage: OP | WORK CLAMP FOOT A_LEFT | WORK CLAMP FOOT A_RIGHT | WORK CLAMP FOOT B_LEFT | WORK CLAMP FOOT B_RIGHT | WORK CLAMP FOOT BLANK_LEFT | WORK CLAMP FOOT BLANK_RIGHT |

|---|---|---|---|---|---|---|

| Figure |  |  |  |  |  |  |

| P/N | 14137608 | 14137509 | 14137905 | 14137806 | 40021870 | 40021869 |

| Guage: OP | WORK CLAMP FOOT_LEFT | WORK CLAMP FOOT_RIGHT |

|---|---|---|

| Figure |  |  |

| Remarks | P/N | P/N |

| D9-14 | 40021872 | 40021871 |

| 12 | 40021875 | 40021874 |

| 10 | 40021878 | 40021877 |

| 14 | 40021881 | 40021880 |